The momentum has not slowed and the finish is in sight. Reassembly of the CB160 continues to go strong and steady. It has taken me many years to learn how much time I need to budget for project completion. In the case of the 65Revive project I had already planned out a reassembly timeline back in September. I am please to say that I am on track and may even be slightly ahead of schedule. I am looking forward to the riding season and want to ensure that the bike is 100% complete before the spring melt off.

I last left off with a rolling chassis and an engine bolted in. Since that time I have been able to reach approximately 98% completion. I have already started fearing potential empty nest syndrome. Like previously posts I’ll take you through the process with pictures.

The powder coating seems to never end. I am hoping this is the last bit of hardware I need to coat, here the the final parts have been blasted. My objective was to NOT use one spec of spray bomb on the bike, I am pleased to announce I have succeeded.

As much as no one wants to run a license plate it is required. I set up some 6061 aluminum on the mill and machined out a nice simple holder. Once complete it was powder coated matte black to blend it in.

The lines of the bike are very crucial therefore fit and finish are a priority. I spent awhile building adjustments into the seat in order to allow it to sit perfectly with the rear frame hoop.

One of the main build objectives was to hide all the wiring. In the case of the handle bars the wiring all got run inside. Holes were drilled and grommets installed to keep things clean.

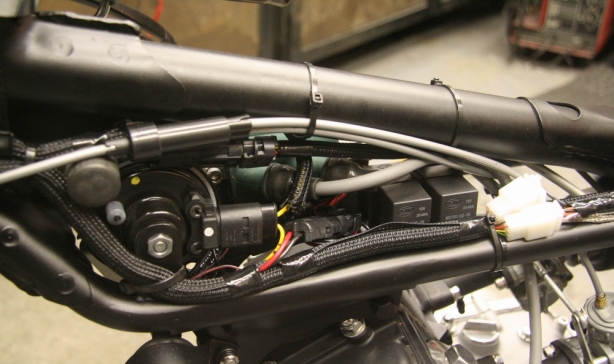

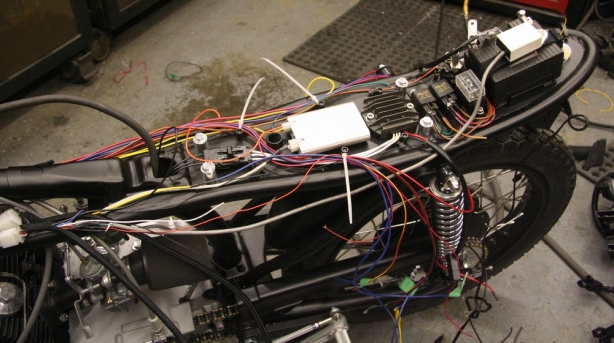

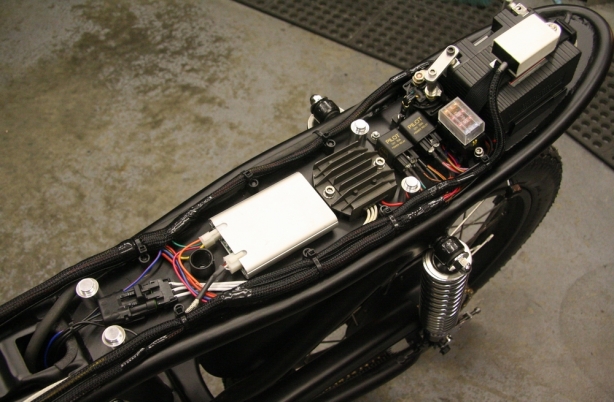

The factory wire harness was of no use to me. Almost every electrical component on the bike had been upgraded or moved. The entire wiring harness was built from scratch. I initially drew out a rough plan on paper but in the end I ended up building it as I went along. Many of the connectors were upgraded to weather pack connectors. All splices were soldered and wrapped with heat shrink.

I am a big believer that even components that are not seen need to be clean and have the same attention to detail. The custom wiring harness cleaned up well in the end and everything tucked in beautifully.

I don’t know why I am posting this picture. Look everyone! I put a new chain on! Whooooopppppppeeee!

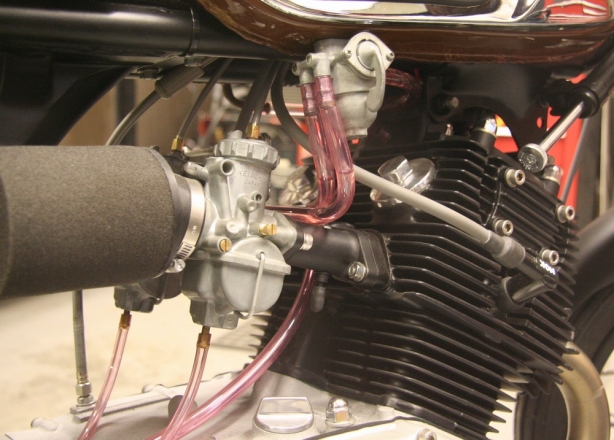

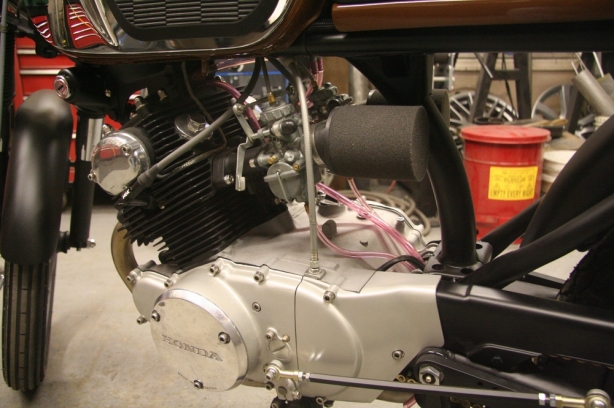

With most of the bike complete I spent some time tuning the carbs and checking the timing. I set it up near the garage door and ran an exhaust hose out so I wouldn’t choke out on the fumes.

Below is video proof the the bike is alive. It starts great and runs. The custom exhaust and muffler sound good.

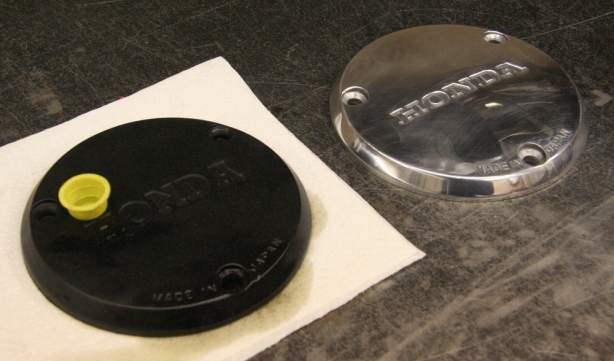

With tuning done and ignition timing confirmed I was able to swap out my timing cover for the NOS Honda stator cover.

From here on in it is basically a picture show. The bike is complete. There are a few details that need to be addressed but I need to wait until I can ride it before I can evaluate what needs to be done.

I opted to mount a super clean button in my steering stem that allows me to cycle through my instrument cluster menus.

Instead of using the factory starter button I chose to mount one next to the ignition switch. I turned the factory starter button, on the throttle housing, into my horn button. I like to think of it as my security system. If someone tries to start the bike they will end up sounding the horn instead of cranking the engine. Ha!

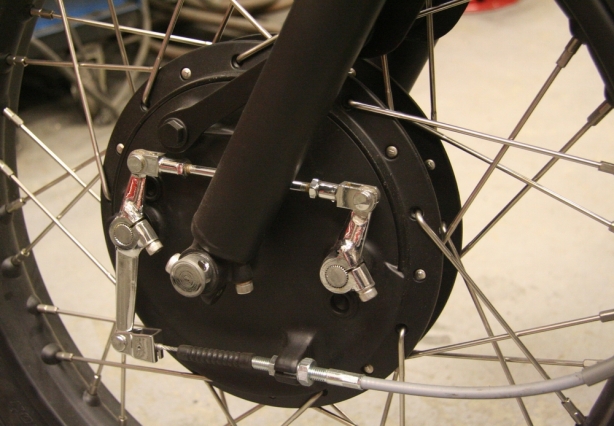

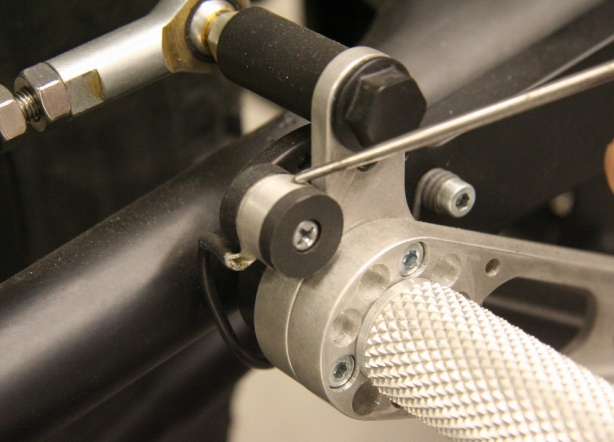

I spent forever obsessing about the rear brake switch. I wanted something clean. I finally came up with the idea of using the rear brake lever stop as the switch. I Machined some plastic bushings in order to insulate the stop. Then using a single ground wire and a 5 pin relay I was able to turn the stop into a switch. Worked great and is almost undetectable.